BT261C

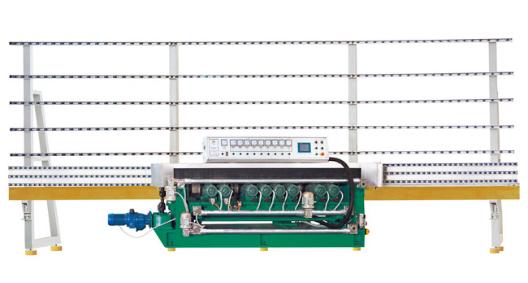

Machine Introduction

- This machine is designed for grinding/polishing bevel edge, with bottom edge grinding.

- Conveyors use chain transmitting system which consist of anti-friction rubber griping pads with reinforced sheet steel bone.

- This structure guarantee glass is stably moved.

- The working precision is high.

- Synchronous tooth belt are used in loading and unloading arms to carry glass, which has a stable transportation.

- Front rail is driven by motors and move in parallel to adapt to different glass thickness.

- Working speed is adjustable by stepless regulator, which offer a wide range of speed selection.

- Working speed and glass thickness appear on digital display.

- Amperometers allow to check wheel absorption and therefore it’s correct functioning.

- Spindles are driven by high precision ABB motors.

- This machine is easy to operate and have a good function.

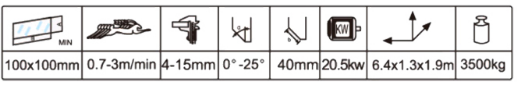

Technical parameters

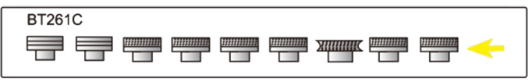

- Spindles: 9 heads.

- Speed: 0.3m-3m/min

- Max. bevel width: 30mm

- Min. glass size: 100mmX100mm

- Glass thickness: 4mm-15mm

- Bevel angle: 0°-15°

- Total power: 21 KW (380V 50Hz)

- Total dimension: 6.4mX1.1mX2.2m

- Weight: 3200Kg