Glass straight line double edger

Machine Introduction

- This machine adopt PLC control and operator interface. The Screen shows every detailed parameters of glass.

- The two conveyor belts are driven by two high precision servo motors.

- The synchronism of transmitting is very high. The torsion of output keeps the constant.

- The mobile grinding section moves along linear twin ball bearing guide.

- The transmission is implemented through twin ball bearing lead screws, which is driven by motor with break.

- The raise/drop of upper tracking system and upper arris motors are driven by motors. It can be set automatically according to different glass thickness input.

- The polishing wheel is operated by air, which can move forwad/back according to glass position.

- This machine use high precision low vibration ABB motor.

- This machine adopt timing belts transmission.

- The machine equipped a auto lubrication pump, which lubricate the lead screw..

- Working speed adjustment through Frequency inverter.

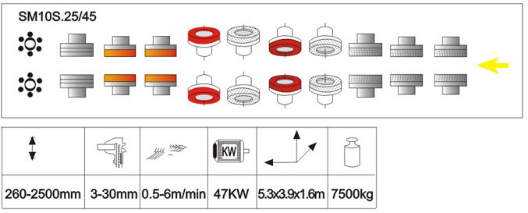

Technical parameters

- Spindles: 22 heads.

- Min. glass width: 260mm

- Max. glass width: 4500mm

- Glass thickness: 3mm-30mm

- Working Speed: 0. 5m-7m/min

- Speed of width adjustment 0-1400 mm/min

- Total power: 50KW

- Working Air pressure 0.15~0.8MPa

- Outer dimension 5301×4421×1606 mm