BT371C

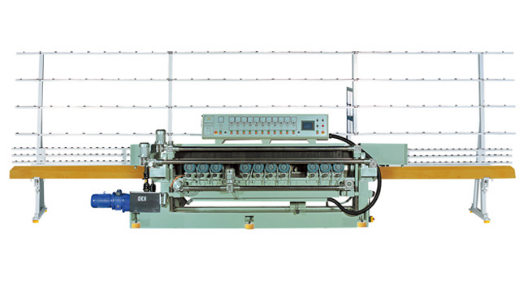

Machine Introduction

- This machine is designed for grinding/polishing bevel edge, with bottom edge grinding.

- This machine adopt PLC control and operator interface (touch panel).

- The motors can be moved as a group. The parameters can be changed though operator interface. The machine can adjust itself according to the parameter input.

- Conveyors use chain transmitting system which consist of anti-friction rubber griping pads with reinforced sheet steel bone. This structure guarantee glass is stably moved. The working precision is high.

- Synchronous tooth belt are used in loading and unloading arms to carry glass, which has a stable transportation.

- Front rail is driven by motors and move in parallel to adapt to different glass thickness.

- Working speed is adjustable by stepless regulator, which offer a wide range of speed selection.

- Spindles are driven by high precision ABB motors.

- This machine is easy to operate and have a good function.

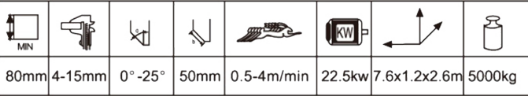

Technical parameters

- Spindles: 11 heads.

- Speed: 0.75m-3.9m/min

- Max. bevel width: 50mm

- Bevel angle: 0°-25°

- Min. glass size: 100mmX100mm

- Glass thickness: 3mm-19mm

- Total power: 22.5KW

- Total dimension: 7.6mX1.2mX2.6m

- Weight: 5000Kg